Feed pelleting

Pelleting as a process of thickening and shaping is widely used in the feed production process. It involves pressing the raw material through the dies holes. The high temperature caused by the addition of steam and significant pressure causes the starch contained in the feed to dissolve, which acts as an adhesive, bonding and maintaining the given shape.

Feed pelleting

Pelleting as a process of thickening and shaping is widely used in the feed production process. It involves pressing the raw material through the dies holes. The high temperature caused by the addition of steam and significant pressure causes the starch contained in the feed to dissolve, which acts as an adhesive, bonding and maintaining the given shape.

Complete pelleting line consist of:

- Pellet mill

- HG sterilizer

- Pellet cooler

- KGR pellet crumblers

- Sifter

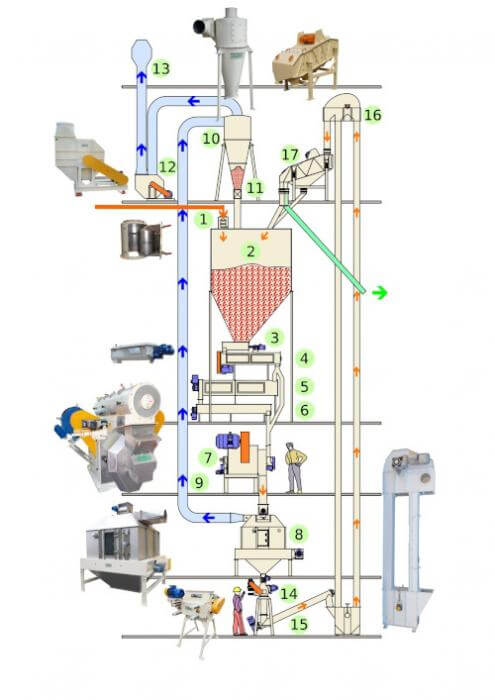

Diagram of the vertical feed pelleting line.

The offered technological lines may include:

1- Magnetic separator

2- Pellet buffer tank,

3- Feeder,

4- Conditioner

5.6- Sterylizer,

7- Pellet mill

8.9- Vertical cooler with air exhaust pipes,

10,11- Cyclone aspiration with a dust lock,

12,13- Fan,

14 – Crumbler,

15 – Screw conveyer,

16 – Bucket elevator

17- Sifter

We offers technological lines having capacities from 1 to 30 t / h

Pellet mills

The Pellet mills consists of a pellet press, conditioner and feeder.

The Pellet press up to 75 kW can be made as a single-engine, and above this power as a twin-engine. The belt transmission used ensures smooth drive transmission and quiet operation.

The feeder’s task is to evenly feed the raw material to the pellet press.

The conditioner is a type of mixer in which as a result of the movement of the blades, the raw material can mix with steam, water, molasses and other additives.

The pellet mill is a safe device in which a number of sensors and blockades are used, whose task is to protect the operators and the device itself.

In order to facilitate the exchange of rollers and dies, an electric lift is used in the pellet mill,

The granulator’s optional equipment is:

- automatic lubrication system (in the pellet mill from PD10 automatic lubrication system is standard),

- front screw feeder,

- devices for spraying liquids directly onto the die on hot pellets,

A complete automation and control system is offered for each pellet mill, thanks to which the pellet mill achieves optimal working parameters

Type | Die diameter [mm] | Power [kW] |

|---|---|---|

PD-1 | 250 | up to 20 |

PD-3 | 305 | up to 45 |

PD-5 | 360 | up to 65 |

PD-10 | 420 | up to 120 |

PD-15 | 550 | up to 220 |

PD-20 | 700 | up to 270 |

PD-30 | 850 | up to 320 |

We offer pellet mills with ring dies best suited to feed production.

We are a producer of dies and rolls, which ensures efficient and short delivery of spare parts for our customers.

The parameters of the pellet mill are closely related to the processed raw material, therefore we consider each project individually, setting up the line so as to obtain the required parameters with minimal power consumption.

Sterylizer

Currently, feeds are increasingly subject to higher quality requirements, especially in the field of feed protection against bacteria, fungi and molds.

This role is fulfilled by a sterylizer whose task is to keep feed previously heated to the required temperature for a period of 3 to 5 min.

The sterylizer is a type of large-diameter screw conveyor in which the feed slowly moves. Warmed and heated walls keep the feed at a constant temperature.

The control elements used: temperature sensors, weight sensor and others lets that the sterylizer operates in automatic mode.

Pellet coolers

Pellets falling out of the pellet press often have a temperature exceeding 80˚C

To be able to store it, it is necessary to cool it to a temperature about 5 ˚ above ambient temperature. This task is fulfilled by thepellets cooler.

We produce coolers in following versions

- horizontal,

- vertical counterflow.

Horizontal coolers

The advantage of horizontal coolers is the smooth, even movement of the granulate on the belt. It causes minimal damage to the granules. Smooth walls made of stainless steel ensure easy falling of the raw material preventing mold growth.

Coolers of this type are best fitted for low buildings. A construction is not required for them. The cooled pellets can go directly to the crumbler or be transported to storage bins.

The coolers are supplied with a fan, cyclone equipped with a dust lock and assembly pipes.

Basic parameters of horizontal coolers.

Type | Capacity [t/h] * |

|---|---|

DP-1 | up to 2 |

DP-3 | up to 4 |

DP-5 | up to 6 |

DP -7 | up to 8 |

DP-10 | up to 10 |

DP-15 | up to 15 |

DP-20 | up to 20 |

* Performance is approximate. It may vary depending on the temperature, moisture of the material, diameter of the pellets and their parameters.

Vertical coolers

The advantage of vertical coolers is a high degree of material cooling. Smooth walls made of stainless steel ensure easy falling of the raw material preventing mold growth.

Coolers of this type are suitable for vertical installations in which a granulator is located above the cooler with a crumbler under the cooler. The cooled pellets can go directly to the crumbler or be transported to storage bins.

The coolers can be supplied with a fan, cyclone equipped with a dust lock and assembly pipes.

Basic parameters of vertical coolers.

Type | Capacity [t/h] * |

|---|---|

CV-1 | up to 2 |

CV-3 | up to 4 |

CV-5 | up to 6 |

CV-8 | up to 8 |

CV-10 | up to 10 |

CV-12 | up to 12 |

CV-16 | up to 16 |

CV-20 | up to 20 |

CV-30 | up to 30 |

* Performance is approximate. It may vary depending on the temperature, moisture of the material, diameter of the pellets and their parameters.

Cyclone

Cyclone are used in pneumatic transport insulations, machine and equipment aspiration installations. Their task is to separate the air and dust mixture. In the cyclone, the dust along with the air goes to the cylindrical chamber in which it is thrown outwards while rotating, and as a result of friction against the walls, the cyclones lose speed and falls by gravity.

Cyclones are an inseparable element of pellets coolers.

Adapting to customer requirements, cyclones can be made right and left (depending on the direction of air intake). Optionally, they can be insulated so that moist air does not condense on the walls of the cyclone.

TESTMER produces cyclones with diameters from 560 to 2000 mm, designed and selected to effectively separate mixtures.

Dust lock

Dust locks are used to dispense loose materials in the form of powders, flour, meals or pellets from spaces where there may be a difference in air pressure.

They are used for emptying accumulated material from cyclones, unloading silos and tanks in which pneumatic and other transport was used.

Basic parameters of dust locks.

Type | Capacity [t/h] * |

|---|---|

SC-200 | up to 6,5 |

SC-250 | up to 15 |

* Performance is approximate. It may vary depending on the temperature, moisture and size of the material.

Fan

Centrifugal fans have been used in aspiration systems for pellet coolers manufactured by TESTMER.

The fans are produced in two versions:

- fans with a rotor mounted directly on the motor axis type WP,

- fans with an impeller mounted on an intermediate bearing shaft, with a drive carried by a WPS type belt transmission.

Adjust to customer requirements, the fans can be made as right and left (depending on the direction of air flow) with a vertical or horizontal outlet.

The fans can be supplied with a frame with anti-vibration insulators, optionally insulated.

Type | Power [kW] |

|---|---|

WP-20 | 2,2 |

WP-22.4 | 4,0 |

| WP-25, WP-35.5 | 5,5 |

| WP-40 | 11,0 |

| WPS-50 | 22,0 |

| WPS-63P, WPS AX63S | 22,0 |

Crumblers

Birds especially in the early stages of development require finely crushed feed because the standard pellets would turn out to be too large. Therefore, crumblers are part of the pellet line. KGR crumblers are double-shaft constructions that ensure a minimum proportion of small parts. They have a simple design. They can be additionally equipped with a roller dispenser and pneumatically controlled bypass system

Crushers offered have a capacity adapted to the overall capacity of the pellet line.

Basic parameters of KGR crumblers.

Type | Capacity [t/h] * |

|---|---|

KGR-1 | up to 1,5 |

KGR-3 | up to 4 |

KGR-5 | up to 6 |

KGR-8 | up to 8 |

KGR-12 | up to 12 |

KGR-16 | up to 15 |

KGR-20 | up to 20 |

Pellets sifter

Siftes are designed for separating materials into two or three dimensional fractions. They are used in feed factories to clean pellets or crumble from lumps and dust.

We offer two types of screeners:

- OW vibrating sifters,

- ORT rotary sifters,

OW vibrating sifters

Inertial vibrating sifters are designed to separate three dimensional fractions. OW have a compact and closed construction that takes up little space in the processing line. The connection to the feeding and receiving devices of the screened material is carried out by means of flexible sleeves, which guarantees the possibility of constructing dust-free technological lines. They are characterized by simplicity of construction and trouble-free operation.

The screen series includes capacities from 5 to 20 t / h

ORT rotary sieves

Rotary sifters are made as two-fraction. Their advantage is minimal damage to the separated material, high efficiency and no vibration, which means that its work does not affect the structural elements of the hall. They are produced for pellets-dust separation with capacities up to 10 to 30 t / h

We please you to familiarize yourself with the entire TESTMER offer.

Gallery

TESTMER - professional solutions for the feed production market

TESTMER WARSZAWA S.A. is the market leader in the production of technological lines for feed production in Poland. From 1991 we installed over 100 lines in Poland, Belarus, Ukraine, Russia, Italy and the Czech Republic.

The basic machine used in the feed production line is a pellet press. TESTMER started production of pelleting presses in 1991 and since then expanded its offer to include all machines related to the feed production process.

We offer warranty and post-warranty service for the feed production equipment purchased from us. Spare parts needed for the proper operation of the devices are produced by our specialized crew in our factory.

cooperation with dozens of

clients